1

2

![]() The shorter Baby construction panels from

ELEMENT-EL Baby 10 are suitable for this application.

When planking with wall-mounted system elements, the

information issued by the respective manufacturer must

be taken into consideration.

The shorter Baby construction panels from

ELEMENT-EL Baby 10 are suitable for this application.

When planking with wall-mounted system elements, the

information issued by the respective manufacturer must

be taken into consideration.

3

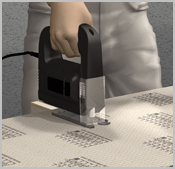

The wall-mounted construction forms the subconstruction, the ELEMENT construction panels are cut to size.

4

Please also observe the information issued by the manufacturer of the wall-mounted elements for assembly direction (vertical or horizontal).

5

The ELEMENT construction panels are glued together with COL-MK. Apply the adhesive to the plate edges as an uninterrupted strand.

6

The screw connection should take place with the washer FIX-S 35 and a suitable screw. Diagonal joints are not allowed. Observe the wall-mounted element manufacturer’s recommendation as to spacing.

7

Planking can be done in full room height or with a shelf above the installations. ELEMENT-EL 20 is suitable for the top covering. This is glued with COL-MK and fixed using FIX-S 35 and a suitable screw.

8

Reinforce all element joints and transitions with glass fibre reinforcement strips ARM-100 SK and ...

9

... finally level out the element joints and the heads of the mounting elements with COL-AK. The surface is now ready for tiling. Further requirements (e.g. sealing) must be taken into consideration in accordance with national directives.

- Practical instructions

-

The basis

Quality with the environment in mind

Working with hard foam support elements

The tools

Recommended cutting techniques for the ELEMENT construction panel

LUX ELEMENTS®- ELEMENT EL

LUX ELEMENTS®- ELEMENT-SL / SQ

Bending radii, slit spacings, dimensions of pre-slit hard foam

Processing instructions with slit panels

LUX ELEMENTS®- ELEMENT-VK

General processing instructions

Processing tips

The following materials are suitable for cladding hard foam support elements

- Application areas

-

Walls in interior areas

Attaching to masonry, concrete or plaster with mortar

Wall levelling over existing tile coverings

The multi-functional construction panel: application on the wall (example)

Application on free-standing metalsupports

The multi-functional construction panel: application on metal stud frame (example)

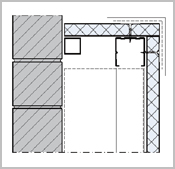

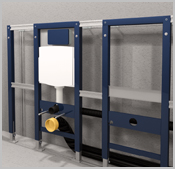

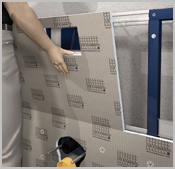

Wall-mounted elements

The creation of a levelling construction

Planking of a support construction

Floor applications

Application on beton or screed

Application on wooden floor boards

Application on the floor

The multi-functional construction panel: on mineral substrate (example)

Floor shower base

- Construction & design

-

With straight panels

Partition walls or room dividers

With slit panels

- Practical examples

- Product

- Datasheets

-

LUX ELEMENTS®- ELEMENT-EL (411 KB) LUX ELEMENTS®- ELEMENT-SL/SQ 30, 50, 80 (134 KB) LUX ELEMENTS®- ELEMENT-VK (411 KB)

- Safety Data Sheets

-

- Installation instructions

- Product & packaging specs

- Systemcomponents

-

The proven and tested system components are fully matched to the processing of the hard foam support elements. The specially developed accessories ensure trouble-free working and high processing reliability.

LUX ELEMENTS®- ARM: Reinforcement fabric LUX ELEMENTS®- COL: Adhesives LUX ELEMENTS®- DRY: Sealing filler and sealing tapes LUX ELEMENTS®- FIX: Fastening sets and plugs/exterior LUX ELEMENTS®- MONT: Mounting aids

![]()

Before printing a pdf file, please check if this is really necessary.

Environmental protection concerns us all.

To view the PDF files, you will need Acrobat Reader that you can download here free-of-charge. This program will enable you to open, view and print out these documents in PDF format.