1

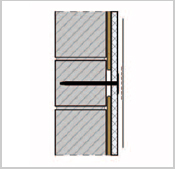

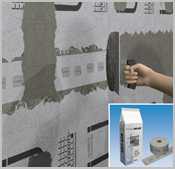

We recommend horizontal laying for ELEMENT-VK on the wall.

2

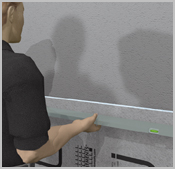

Before attaching, if possible, position the alignment markings on the floor and ceiling. Then press on the ELEMENT with the level and spirit level and check not only the individual and reciprocal vertical and horizontal alignment of the ELEMENT construction panels.

3

4

5

- Practical instructions

-

The basis

Quality with the environment in mind

Working with hard foam support elements

The tools

Recommended cutting techniques for the ELEMENT construction panel

LUX ELEMENTS®- ELEMENT EL

LUX ELEMENTS®- ELEMENT-SL / SQ

Bending radii, slit spacings, dimensions of pre-slit hard foam

Processing instructions with slit panels

LUX ELEMENTS®- ELEMENT-VK

General processing instructions

Processing tips

The following materials are suitable for cladding hard foam support elements

- Application areas

-

Walls in interior areas

Attaching to masonry, concrete or plaster with mortar

Wall levelling over existing tile coverings

The multi-functional construction panel: application on the wall (example)

Application on free-standing metalsupports

The multi-functional construction panel: application on metal stud frame (example)

Wall-mounted elements

The creation of a levelling construction

Planking of a support construction

Floor applications

Application on beton or screed

Application on wooden floor boards

Application on the floor

The multi-functional construction panel: on mineral substrate (example)

Floor shower base

- Construction & design

-

With straight panels

Partition walls or room dividers

With slit panels

- Practical examples

- Product

- Datasheets

-

LUX ELEMENTS®- ELEMENT-EL (0 Byte) LUX ELEMENTS®- ELEMENT-SL/SQ 30, 50, 80 (0 Byte) LUX ELEMENTS®- ELEMENT-VK (0 Byte)

- Installation instructions

- Test certificates

-

Fire performance evaluation of EL 80 with ceramic tiles, in accordance with the 2006 edition of national fire protection association 286 (0 Byte)04/2008\\Test date, april 23, 2008. SwRI Project No.: 01.13544.01.216a

Fire performance evaluation of EL 80, in accordance with the 2006 edition of national fire protection association 286 (0 Byte)04/2008\\Test date, april 23, 2008. SwRI Project No.: 01.13544.01.216b

Investigation of the surface burning characteristics of a nominal 0.32-in. thick polysterene foam, encapsulates in glass fiber mesh and mortar (supported over wire and rods) (0 Byte)06/2007\\Test date, june 11, 2007. SwRI Project No.: 01.12693.01.149c

Investigation of the surface burning characteristics of a nominal 0.5-in. thick polysterene foam, encapsulates in glass fiber mesh and mortar (supported over wire and rods) (0 Byte)06/2007\\Test date, june 12, 2007. SwRI Project No.: 01.12693.01.149f

Investigation of the surface burning characteristics of a nominal 0.8-in. thick polysterene foam, encapsulates in glass fiber mesh and mortar (supported over wire and rods) (0 Byte)06/2007\\Test date, june 12, 2007. SwRI Project No.: 01.12693.01.149g

Investigation of the surface burning characteristics of a nominal 3.25-in. thick polysterene foam, encapsulates in glass fiber mesh (0 Byte)06/2007\\Test date, june 12, 2007. SwRI Project No.: 01.12693.01.149e

Investigation of the surface burning characteristics of a nominal 3.25-in. thick polysterene foam, encapsulates in glass fiber mesh and mortar with a tile face (0 Byte)06/2007\\Test date, june 11, 2007. SwRI Project No.: 01.12693.01.149d

- Product & packaging specs

- Systemcomponents

-

The proven and tested system components are fully matched to the processing of the hard foam support elements. The specially developed accessories ensure trouble-free working and high processing reliability.

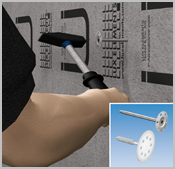

LUX ELEMENTS®- ARM: Reinforcement fabric LUX ELEMENTS®- COL: Adhesives LUX ELEMENTS®- DRY: Sealing filler and sealing tapes LUX ELEMENTS®- FIX: Fastening sets and plugs/exterior LUX ELEMENTS®- MONT: Mounting aids

![]()

Before printing a pdf file, please check if this is really necessary.

Environmental protection concerns us all.

To view the PDF files, you will need Acrobat Reader that you can download here free-of-charge. This program will enable you to open, view and print out these documents in PDF format.