Instruction

The processing information provided as follows applies to all panel thicknesses of the fleece-backed construction panel ELEMENT-VK

1 - General

The sealing construction panel ELEMENT-VK is a completely tested system with coordinated system components.

2 - Wall application

Depending on the evenness of the substrate, apply the fixing adhesive COL-AK pointwise on one side using dots of adhesive (8–10 pcs. per m²).

3 - Wall application

For uneven substrates, the full-surface application of the fixing adhesive COL-AK with a toothed trowel is possible.

4 - Wall application

We recommend horizontal laying for ELEMENT-VK. Draw alignment markings before application, if possible. Press on ELEMENT-VK with level and spirit level.

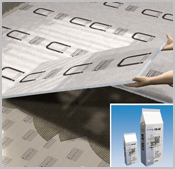

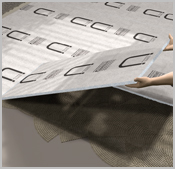

Floor application (on mineral substrate)

Apply COL-AK fixing adhesive with a toothed trowel (depending on the substrate, at least 6 mm) to evenly cover the surface. Dot laying is possible from EL-VK 30 (dot spacing approx. 20 cm).

6 - Floor application (on wooden floors)

First lay ELEMENT-Baby 4 in bond on the floor and fix with suitable screws using FIX-S 35 fastening washers. Glue ELEMENT-VK on this substrate over the full surface with fixing adhesive COL-AK.

7 - Floor application (on wooden floors)

Dot laying is possible from EL-VK 30. The spacing of the mortar dots should be approx. 20 cm. Preparation of the substrate as described in 6

8 - Floor application (on pre-treated wooden floors)

Full-surface laying on uneven wooden floors is also possible on primed, filled floors using EL-VK as an alternative.

9 - Transitions (floor application)

Sealing of the joints takes place using sealing tape DRY-DBV and DRY-ASK. DRY-ASK is applied using a brush or spatula. Gluing of the sealing tape takes place using DRY-ASK. In the second step the joint is levelled out using DRY-ASK.

10 - Transitions

The sealing of the joints on the wall and the joints between the wall and the floor takes place using sealing tape DRY-DBV and DRY-ASK. The same method as described in 9.

11 - Transitions

Prefabricated DRY-DBVIE (inner corners) must to be used for inner corners. These are correspondingly bonded with DRY-ASK (using the method described in Item 9).

12 - Transitions

Prefabricated DRY-DBVAE (outer corners) must to be used for inner corners. These are correspondingly bonded with DRY-ASK (using the method described in Item 9).

13 - Wall penetrations

The connection to wall penetrations takes place via the expansion zone sleeve DRY-DBDZM which is glued in with DRY-ASK as described in Item 9.

14 - Tiles using

Application of tiles using COL FLEX. COL-FBK is additionally possible on the floor. Apply it over the full surface using a toothed trowel.

- Practical instructions

-

The basis

Quality with the environment in mind

Working with hard foam support elements

The tools

Recommended cutting techniques for the ELEMENT construction panel

LUX ELEMENTS®- ELEMENT EL

LUX ELEMENTS®- ELEMENT-SL / SQ

Bending radii, slit spacings, dimensions of pre-slit hard foam

Processing instructions with slit panels

LUX ELEMENTS®- ELEMENT-VK

General processing instructions

Processing tips

The following materials are suitable for cladding hard foam support elements

- Application areas

-

Walls in interior areas

Attaching to masonry, concrete or plaster with mortar

Wall levelling over existing tile coverings

The multi-functional construction panel: application on the wall (example)

Application on free-standing metalsupports

The multi-functional construction panel: application on metal stud frame (example)

Wall-mounted elements

The creation of a levelling construction

Planking of a support construction

Floor applications

Application on beton or screed

Application on wooden floor boards

Application on the floor

The multi-functional construction panel: on mineral substrate (example)

Floor shower base

- Construction & design

-

With straight panels

Partition walls or room dividers

With slit panels

- Practical examples

- Product

- Datasheets

-

LUX ELEMENTS®- ELEMENT-EL (0 Byte) LUX ELEMENTS®- ELEMENT-SL/SQ 30, 50, 80 (0 Byte) LUX ELEMENTS®- ELEMENT-VK (0 Byte)

- Installation instructions

- Test certificates

-

Fire performance evaluation of EL 80 with ceramic tiles, in accordance with the 2006 edition of national fire protection association 286 (0 Byte)04/2008\\Test date, april 23, 2008. SwRI Project No.: 01.13544.01.216a

Fire performance evaluation of EL 80, in accordance with the 2006 edition of national fire protection association 286 (0 Byte)04/2008\\Test date, april 23, 2008. SwRI Project No.: 01.13544.01.216b

Investigation of the surface burning characteristics of a nominal 0.32-in. thick polysterene foam, encapsulates in glass fiber mesh and mortar (supported over wire and rods) (0 Byte)06/2007\\Test date, june 11, 2007. SwRI Project No.: 01.12693.01.149c

Investigation of the surface burning characteristics of a nominal 0.5-in. thick polysterene foam, encapsulates in glass fiber mesh and mortar (supported over wire and rods) (0 Byte)06/2007\\Test date, june 12, 2007. SwRI Project No.: 01.12693.01.149f

Investigation of the surface burning characteristics of a nominal 0.8-in. thick polysterene foam, encapsulates in glass fiber mesh and mortar (supported over wire and rods) (0 Byte)06/2007\\Test date, june 12, 2007. SwRI Project No.: 01.12693.01.149g

Investigation of the surface burning characteristics of a nominal 3.25-in. thick polysterene foam, encapsulates in glass fiber mesh (0 Byte)06/2007\\Test date, june 12, 2007. SwRI Project No.: 01.12693.01.149e

Investigation of the surface burning characteristics of a nominal 3.25-in. thick polysterene foam, encapsulates in glass fiber mesh and mortar with a tile face (0 Byte)06/2007\\Test date, june 11, 2007. SwRI Project No.: 01.12693.01.149d

- Product & packaging specs

- Systemcomponents

-

The proven and tested system components are fully matched to the processing of the hard foam support elements. The specially developed accessories ensure trouble-free working and high processing reliability.

LUX ELEMENTS®- ARM: Reinforcement fabric LUX ELEMENTS®- COL: Adhesives LUX ELEMENTS®- DRY: Sealing filler and sealing tapes LUX ELEMENTS®- FIX: Fastening sets and plugs/exterior LUX ELEMENTS®- MONT: Mounting aids

![]()

Before printing a pdf file, please check if this is really necessary.

Environmental protection concerns us all.

To view the PDF files, you will need Acrobat Reader that you can download here free-of-charge. This program will enable you to open, view and print out these documents in PDF format.